Vishrudh Sriramprasad

Graduate Research Aide, Center for Negative Carbon Emissions at Arizona State University

Decarbonizing the economy and transitioning to renewable energy sources are critical to meeting the goals set in the 2016 Paris Climate Agreement. Unfortunately, the consensus among climate scientists is that these efforts are no longer enough to adequately mitigate climate change. In their latest assessment, the Intergovernmental Panel on Climate Change (IPCC) asserts that we need to start removing CO2 from the atmosphere using a suite of technologies called Carbon Dioxide Removal (CDR).1 The IPCC contends that the worst effects of climate change can be avoided by using CDR to offset some of the CO2 we’re still emitting, and eventually decrease the CO2 concentration in the atmosphere to safer levels.

One of the prominent CDR pathways expected to play a role over the next century is called Direct Air Capture (DAC)—a technology that removes CO2 from the atmosphere without using photosynthesis. DAC is highly attractive because unlike other technologies such as biomass carbon removal and storage, it does not require large swaths of land to scale up. Additionally, since DAC captures CO2 from ambient air, it can be positioned anywhere, allowing it to be co-located with end-use partners, whether that be carbon storage or CO2 utilization.

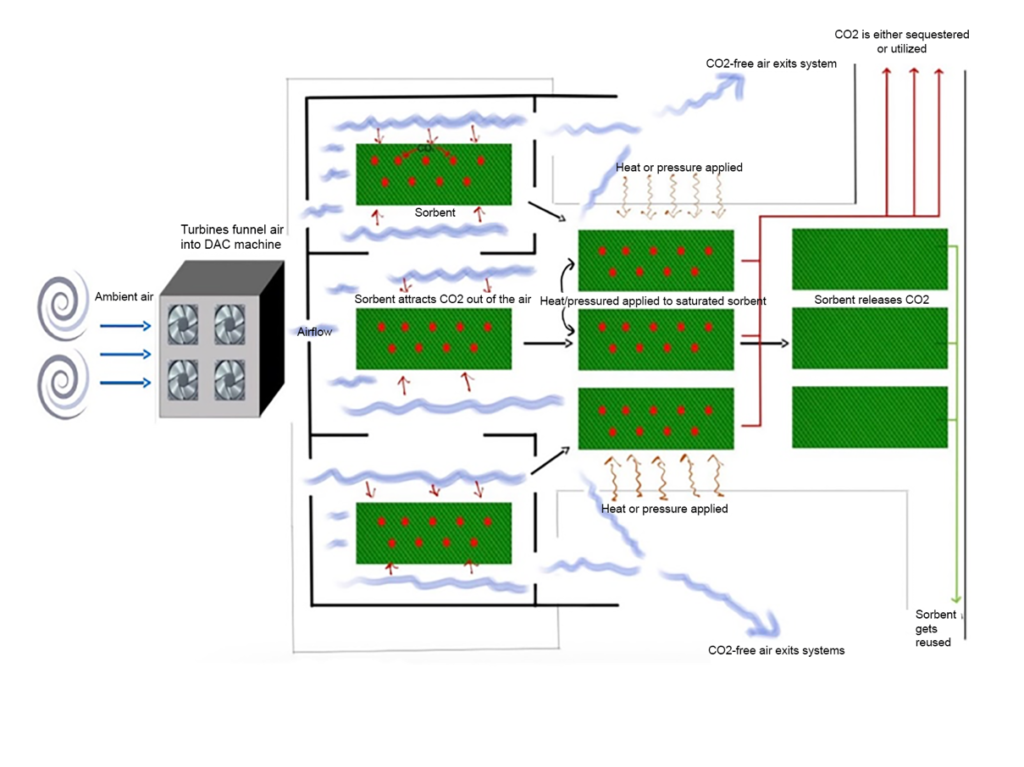

Current DAC designs are typically large facilities that use fans to funnel ambient air near ground level into contact with a CO2-attractive sorbent or solvent. After the CO2 molecules attach to the sorbent, the rest of the air is released back into the atmosphere. Once the sorbent is saturated with CO2, heat and/or pressure is applied, and the CO2 molecules get released in a process called regeneration, creating a highly concentrated stream that can be directed toward storage or utilization facilities.

This design, although demonstrated by a few companies at pilot scale to be effective, has unfeasibly high energy and financial costs. To address this issue, Arizona State University’s (ASU) Center for Negative Carbon Emissions is working with private industry on innovative energy- and cost-reduction solutions.

The MechanicalTreeTM is a unique DAC system technology based on the latest innovations of ASU’s Dr. Klaus Lackner, being designed, tested, and manufactured by Carbon Collect Limited. The design is passive and thus, does not require the use of energy-intensive fans to funnel air into the system. Instead, the MechanicalTree™ relies on wind to bring air in contact with a sorbent, significantly reducing operation costs compared to those of other contemporary designs. The MechanicalTree™ is a cylindrical structure roughly five feet in diameter that, when fully deployed, stands a little taller than a two-story building at approximately 32 feet. The sorbent that captures the CO2 is supported on large thin disks stacked vertically with gaps for natural air convection. When the sorbent is saturated with CO2, the disk stack is collapsed and sealed into the base of the MechanicalTree,™ which is approximately eight feet high. In the base, the sorbent is regenerated. After regeneration, the MechanicalTree™ expands to its full height once again and the process starts over. The captured CO2 can be sequestered underground for permanent disposal, or purified and compressed, and used for a variety of purposes.

Carbon Collect’s MechanicalTree™ embodies a small modular design strategy. As opposed to building large DAC plants which will operate for several decades using the same technology, Carbon Collect plans to rapidly iterate on smaller capacity systems, allowing for frequent and adaptable design improvements, which will significantly shorten the cycle time for next-generation systems. Due to their technology’s small modular design, Carbon Collect can match the capacity of large DAC plants by mass producing and deploying their MechanicalTree™ in “farms” for carbon capture and sequestration. They will also be able to deploy smaller capacity systems to meet more niche target markets like supplying greenhouses and vertical farms with CO2, and other commercial use projects. The mass production of MechanicalTree™ will drive down costs in the medium-to-long term2 and allow Carbon Collect to provide a scalable and affordable tool for climate change mitigation.

Though mass production is still a ways off, small-scale implementations are underway. At ASU’s Tempe Campus, a commercial scale MechanicalTree™ DAC system has been in operation since the spring of 2022. In addition to serving as a demonstration unit, it is rigged with instrumentation for ongoing experimental testing and development of future improvements. Researchers at ASU’s Center for Negative Carbon Emissions will be performing exhaustive experiments and testing on this device, determining performance under different weather conditions, and developing next generation models. With the commissioning of this first MechanicalTree system, Carbon Collect and ASU have taken a huge step toward large-scale commercial deployment.

The I-WEST team is investigating how industries in the Intermountain West can integrate DAC and how the technology might evolve in the region. With its many days of sunshine, open land, and good sequestration geology, the Intermountain West could be an industrial center for DAC. And, by concentrating fabrication and deployment efforts in rural locations, there’s great potential for upgrading the economic opportunities of those areas.

References

- IPCC, 2021: Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change [Masson-Delmotte, V., P. Zhai, A. Pirani, S.L. Connors, C. Péan, S. Berger, N. Caud, Y. Chen, L. Goldfarb, M.I. Gomis, M. Huang, K. Leitzell, E. Lonnoy, J.B.R. Matthews, T.K. Maycock, T. Waterfield, O. Yelekçi, R. Yu, and B. Zhou (eds.)]. Cambridge University Press. In Press

- S. Lackner, H. Azarabadi, “Buying Down the Cost of Direct Air Capture”, Industrial & Engineering Chemistry Research, Vol 60, Iss. 22. May 26, 2021.